The machine had been given to a colleague of mine who is a wiz with fancy dress. She didn't feel it was really the machine for her so the 28 had been stored under her desk at the office for some months.

When it arrived there really wasn't much wrong with it. It looked like it hadn't been used for a long time and although slightly dulled and with a few blemishes there were no signs of significant rust. It came with the essentials; a fixed straight-stitch foot, a shuttle, one bobbin and a blunt needle. The only real problem was that the check spring, which on Singer 27/127 and 28/128, is comparatively long, unguarded and therefore vulnerable to damage, had been snapped.

The check spring is the fine wire spring which will usually be found somewhere in the region of a sewing machine's tension disks. It's job is to remove slack in the thread as the take up arm rises to the top of its stroke after the stitch has been formed. If the tension on the check spring is too little or the spring is missing the machine will be unable to form good stitches.

This machine was actually able to form a pretty good stitch even without a properly functioning check spring. However I knew it would do better if it was in tip-top condition so I bought a new one. If you are looking for one it is worth knowing that a spring from a 27 will fit a 28 and vice versa.

The new check spring has a loop at one end for the thread, a long straight section, a row of even coils and one small coil at the end. The whole thing slips neatly over the tension assembly stud.

The stud is threaded at both ends. The narrow thread screws directly into the machine head and the split end allows the pressure on tension discs to be varied.

This photo shows the check spring in position over the tension stud. The tail of the spring will be sandwiched between the step in the stud and the machine head casting. This holds the spring in place and under tension.

The check spring's travel is limited top and bottom by the two notches on the machine head casting but the arm of the spring should sit on the lug mid way between these two. The position can fine tuned by loosening the screw at the bottom of the tension assembly and sliding the slotted back plate to the left or right.

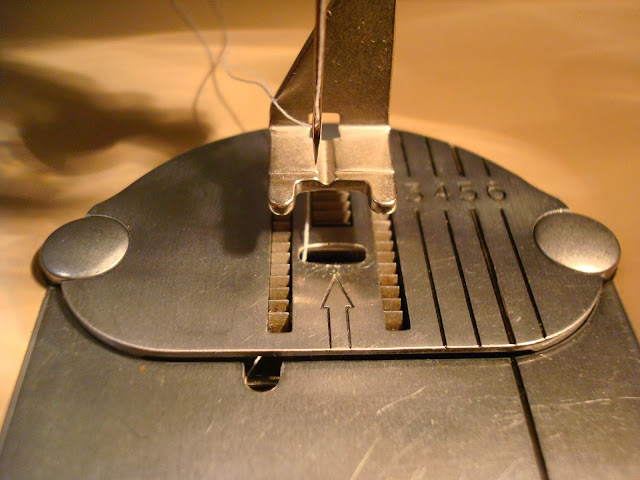

Here is a detail of the tension unit after reassembly. The knurled nut adjusts the upper tension and shouldn't need to be much tighter than in the picture if the bottom tension is set up correctly.

With a new check spring the Singer 28k is now producing beautiful, even, balanced stitches. Not bad work for a 115 year old!