The poor quality of these stitches in spite of many rethreadings and much adjustment of the top tension were rapidly making me fall out of love with this machine. I have often thought of the 15 as a bit of an odd ball in the Singer stable with its odd man out bobbin and bobbin case. Three of my machines take class 66 bobbins so why did I even need the hassle of yet another type of bobbin? For a few minutes I even considered throwing in my lot with the 15k80 and selling it.

Instead I did some thinking and research and came to the conclusion that my problems were, more than likely, related to bottom tension.

It took me quite some time before I could find some really useful practical advice on how to set up from scratch a class 15 bobbin case. One method I watched on You Tube relied on buying a new bobbin case set up at the factory and then pulling yards and yards of thread through the tension until you develop a 'feel' for what should be the right tension - er there must be a more scientific way than that…!

And of course there is. A big thank you to Charles Day who submitted these instructions to singersewinginfo.co.uk helping people like me (and you?) to improve the performance of their vintage Singers.

Step 1: weigh out just under one and a half ounces of sugar

Step 2: put the sugar inside a tiny ziplock back. The one I used came with spare buttons for one of The Much Beloved's shirts and was just the right size.

Step 3: Tie the bobbin thread to the bag of sugar. My bag happened to have a small hole punched in it for just that job.

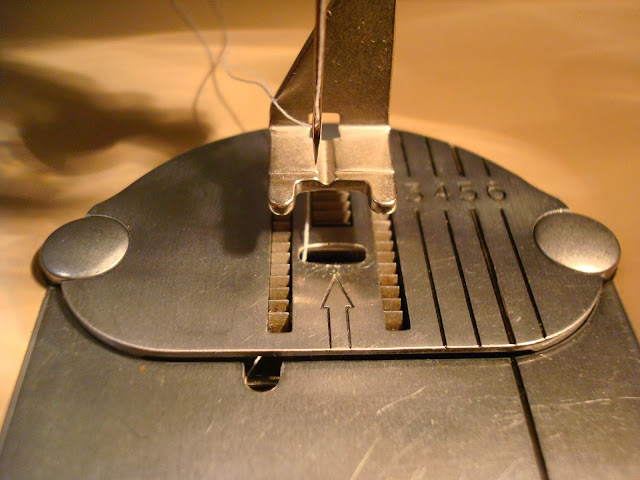

Step 4: Load the bobbin into the bobbin case. The first time I did this I discovered that the tension on this bobbin case was so light that the bag of sugar quickly dropped to the floor sending the bobbin spinning in its case. Ah-Ha! So there's the cause of my sloppy stitches and inconsistent tension.

Step 5: Using the small screwdriver; little by little I tweaked up the tension until it was sufficient to just hold the bag swinging in mid air. A sharp upward motion should allow one to two inches of thread to be pulled off the bobbin before it comes to rest in mid air again.

Step 6: Load the bobbin and case into the machine; check the thread path of the top thread; adjust top tension to balance the top and bottom threads; admire the beautiful even straight stitches produced by class 15 Singers. I think I may have just found a new favourite.