I am rather taken by the Merchant & Mills SEWING BOOK. It's an aesthetically pleasing object in its own right and the projects inside are, for the main part, non-gender-specific which makes a welcome change for the male seamster.

As a confirmed old bachelor with some heavy unbleached calico on his hands I figured that a Hussif is the nearest I am likely to get to a housewife and resolved to knock one up [perhaps I should rephrase that!?]

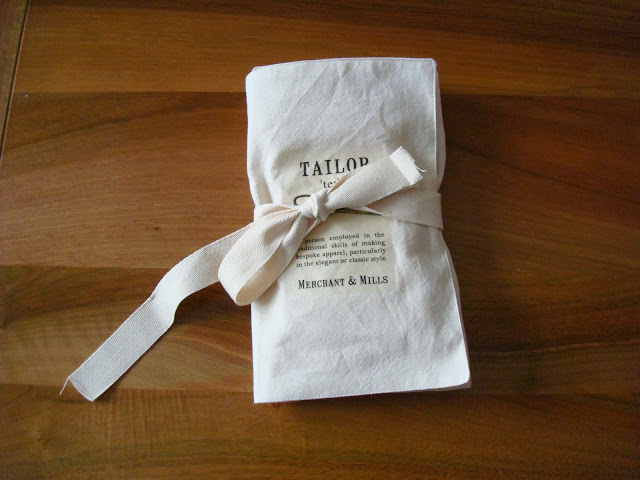

Here are some pictures of my version

There are seven pockets for

Here is the Hussif all furled up and tied shut. To give you an idea of size the cotton webbing tape is 25mm (yes I've gone metric today) or one inch wide. I may trim the tape down a bit once things have stretched out a bit.

The first of two big adventures in making this project was printing the downloadable Merchant and Mills graphic onto what can only be described as magic paper and then transferring this to the front of the Hussif using the iron.

I think I may have overcooked the transfer slightly and the instructions on where to position it were not Gavin-proof (I may have got the graphic upside down) but overall I am pleased with the effect. I am left with some mixed feelings about putting a company logo onto an item I have made but I like the look of the finished project and I have tried out something I never would have done otherwise. My mind is now teaming with ideas for some kind of Oil & Thread transfer. Possibly featuring a hen if I can find copyright free image to use.

Adventure number two is a Singer 401G related discovery and one for the seam guide junkies amongst us (you know who you are). I have discovered that the toe of the general purposes foot can be made to sit under the seam guide. This is shown in the section of the Manual which shows how to blind stitch hems using the "BO" setting. I realised that, with the needle centred (red lever at position 3), this gives scant ⅛ seam allowance.

When would want a scant ⅛ seam allowance? Well I found it handy when edge stitching the Hussif. I hope you agree that the results are pretty tasty.

I am planning to hold on to this particular Hussif myself. I have something in mind for it. I really enjoyed putting this together. It's a good way to spend a Saturday afternoon. At this point in September I am thinking that one or two of these, filled with some 'heritage' style notions might make good Christmas presents.