This arrived last week. It was just in time to make the buttonholes on the French back boxers. I am rather taken with it for a number of reasons - the funky box is only one of them.

According to the back of the box Greist seem to have offered a bewildering range of buttonholers, no fewer than ten, to suit every conceivable sewing machine. Make sure you get the right one. For standard low shanks (like my Singers 15K, 28K, 99K and 201K) it's model #1. If you're looking for a buttonholer to suit a Singer slant shank it's model #5.

Inside the box is the buttonholer itself;

cover plate and screw;

five button hole templates;

and (best of all in some respects) the instruction book.

The instructions are copyrighted 1966 so the buttonholer can't be any earlier than that although I am given to understand that Greist produced this design of buttonholer we'll into the 1980s. I love the colour of the buttonholer and the instructions it looks very mid sixties to me.

The instructions are really well written and even offers tips on what size thread and needles to use. I was interested and delighted to read the following Special Note which I have never seen in a Singer instruction booklet!

This buttonholer should come with five templates - 5/16", 5/8", 13/16", 1 1/16" (straight and keyhole). Mine came with a rather odd, but useful, mix 5/16", 1/2", 5/8", 7/8" keyhole and eyelet. The templates are plastic but as far as I can gather earlier versions used pot metal ones and they are interchangeable. Even better than that, Greist made buttonholers for Singer and the templates from these are also interchangeable.

This buttonholer is smooth and surprisingly quite in use and makes great buttonholes. I think this one is going to be getting a lot of use probably with the Singer 201K with dropped feed dogs.

I love the back of the instruction manual as a parting shot!

Thursday, 24 October 2013

Sunday, 20 October 2013

Simplicity 1960: French Back Boxer Shorts - Pt II

Here are the finished boxers. I added the buttonholes using my new toy a Griest #1 template buttonholer for low shank machines (this means YOU Mr Singer 201K). I was very happy with the results. I am planning a full photo-tour and review of the new (to me) buttonholer in a future post.

Front and back there are seven half-inch buttonholes and one additional thirteen-sixteenths vertical buttonhole which allows the waistbands to cross at the back. It's a lot of work but we all get a buzz out of using an automatic buttonhole attachment right?

The position of the buttons at the back give a range of adjustment for expanding and contracting waists. I think this design must have arisen from wartime and post war shortages of elastic.

The half inch (12mm) buttons I used were saved from shirts I cut up last year to turn into my first quilt. There a total of nine so I think can be forgiven for sewing them on with the Singer 401G. I used white thread to match the buttons rather than pink to match the shorts. Sewing buttons on with a vintage Singer is probably worth a post all of its own sometime soon.

I am happy with the way these turned out but. I will need to forget how much work they are before I am tempted to make them again.

Saturday, 19 October 2013

Simplicity 1960: French Back Boxer Shorts - Pt I

I have had this pink and blue striped cotton shirting for months. I picked it up cheaply on eBay. I washed it to preshrink it ages ago and then it took me ever so long to remember to take it with me to the shops so that I could buy matching thread. I no longer trust my memory of colour to buy thread. Unless it's black or white. After the fabric was preshrunk I was left with just under two yards.

That's a slightly awkward yardage - not really enough for a shirt. I decided that the only option would have to be boxers. I had a bit of spare time on my hands so I elected to make one of the most complicated patterns for boxer shorts in the world: Simplicity 1960 ©1945.

I have made boxers from this pattern once or twice before, retracing and redrafting the pattern to allow for my ample girth ©2013. I pressed the pattern pieces and fabric in the usual way prior to cutting out. I cut out using the rotary cutter with the help of Ramses II and Venus who always like to get in on the act at this stage.

The first step is to make two pleats in the fronts of the boxers. These are clearly marked on the pattern pieces and the stripes on the fabric certainly help.

I secured the pleats with pins.

Last Sunday we did some organising in the sewing room so now I can used the Singer 201K in it's No.41 cabinet. It's the first time it has seen any treadle action since the arsenic green Negroni shirt back in June! I've rather missed it. It's now positioned to the right of a window so the light, by day, is good. I set the stitch length to the longest tacking/basting stitch 6spi.

And sewed about ¼ inch from the top of the boxers to secure the pleats.

The next step is to secure the two fronts together at the crotch seam using a flat felled seam. This is a little tricky as the seam allowance has a curved taper from ⅝ inch down to nothing. Careful pressing and folding and a slow but steady foot on the treadle are a must. Lightly marking the sewing line with a pencil doesn't hurt either.

Here both fronts have been pleated and joined at the crotch.

I then turned my attention to the seat panel and the questionable pleasure of creating a continuous lap. The first time I made this pattern I actually had to look up what it was. Thank goodness for the Internet-o-graph!

And then (and this is the really silly bit) you have to open the V up until it as near a straight line as possible and pin a strip of fabric along the raw edge.

And then (the silly and HARD bit) stitch it - oh so carefully! - in place in such a way that the line of stay stitching will be enclosed.

Finally the raw edge of the strip is turned under and the fold top stitched to the right side of the seat panel. This forms a sort of gusset. I didn't find it easy. It's well worth practising with scraps. The pattern instructions call for a one inch strip for the binding. Make it a generous inch. I made mine nearer 1⅛ inch and was satisfied with the result.

After all that fuss sewing the seat panel to the fronts and joining the legs (all with flat felled seams) seams like child's play.

Here is where I ran out of steam. The basic construction is complete with the two part yoke sewn to the wrong side of the shorts, folded over and then edge stitched to the right side.

The boxers still lack a hem, button holes, and buttons but they will have to wait for another day. At the back the two piece yoke combines with the continuous lap to form an adjustable waistband which negates the need for elastic. How's that for austerity spec?!

That's a slightly awkward yardage - not really enough for a shirt. I decided that the only option would have to be boxers. I had a bit of spare time on my hands so I elected to make one of the most complicated patterns for boxer shorts in the world: Simplicity 1960 ©1945.

I have made boxers from this pattern once or twice before, retracing and redrafting the pattern to allow for my ample girth ©2013. I pressed the pattern pieces and fabric in the usual way prior to cutting out. I cut out using the rotary cutter with the help of Ramses II and Venus who always like to get in on the act at this stage.

The first step is to make two pleats in the fronts of the boxers. These are clearly marked on the pattern pieces and the stripes on the fabric certainly help.

I secured the pleats with pins.

Last Sunday we did some organising in the sewing room so now I can used the Singer 201K in it's No.41 cabinet. It's the first time it has seen any treadle action since the arsenic green Negroni shirt back in June! I've rather missed it. It's now positioned to the right of a window so the light, by day, is good. I set the stitch length to the longest tacking/basting stitch 6spi.

And sewed about ¼ inch from the top of the boxers to secure the pleats.

The next step is to secure the two fronts together at the crotch seam using a flat felled seam. This is a little tricky as the seam allowance has a curved taper from ⅝ inch down to nothing. Careful pressing and folding and a slow but steady foot on the treadle are a must. Lightly marking the sewing line with a pencil doesn't hurt either.

Here both fronts have been pleated and joined at the crotch.

I then turned my attention to the seat panel and the questionable pleasure of creating a continuous lap. The first time I made this pattern I actually had to look up what it was. Thank goodness for the Internet-o-graph!

The first step is to stay stitch a V either side of the centre back. The pattern has this V marked on it. I marked it lightly on the fabric with a sharp pencil.

I then carefully slashed between the two lines of stay stitching - making sure not cut through the line of stitches.

And then (and this is the really silly bit) you have to open the V up until it as near a straight line as possible and pin a strip of fabric along the raw edge.

And then (the silly and HARD bit) stitch it - oh so carefully! - in place in such a way that the line of stay stitching will be enclosed.

Finally the raw edge of the strip is turned under and the fold top stitched to the right side of the seat panel. This forms a sort of gusset. I didn't find it easy. It's well worth practising with scraps. The pattern instructions call for a one inch strip for the binding. Make it a generous inch. I made mine nearer 1⅛ inch and was satisfied with the result.

After all that fuss sewing the seat panel to the fronts and joining the legs (all with flat felled seams) seams like child's play.

Here is where I ran out of steam. The basic construction is complete with the two part yoke sewn to the wrong side of the shorts, folded over and then edge stitched to the right side.

The boxers still lack a hem, button holes, and buttons but they will have to wait for another day. At the back the two piece yoke combines with the continuous lap to form an adjustable waistband which negates the need for elastic. How's that for austerity spec?!

Saturday, 12 October 2013

Wrap Around Pinny Finished

This is one of those sewing projects that stalled and would not restart for some time. It was nearly finished for ages but now it is really finished.

If I had a dress form I could have shown this off a little better but the coat hanger give some idea. The pinny crosses over at the front and ties with a slim bow at the back.

The two ties are secured at the waist with a rectangle of topstitching on the inside of the pinny.

The tie on the left front passes through a small gap in the side seam under the armhole on the righthand side of the pinny. I reinforced this with some back and forward stitches rather than a worked buttonhole. This is a utility garment after all.

The stalling point for me was the bias binding. There must be about five yard of the stuff on this garment. I made my own and first tried to attach it with the vintage binding foot on the Singer 99K. The straights went well but it struggles with sharper curves and crossing seams. I had to unpick the dodgy bits and go back over them with the regulars straight stitch foot.

I didn't even attempt it on the armholes. I went out and bought a bias binder maker which is loads of fun to use and attached the binding by pinning and sewing once through all five layers. Not the finest of finishes but fine for doing the dishes in.

Not that I will be wearing it for washing the dishes or scrubbing the front step. It's far too small. It has however provided me with practice using bias binding and probably the confidence to have a go at making a dressing gown sometime soon.

Sunday, 29 September 2013

Baby Fence Rail Quilt - Pt VII: The Big Finish

The Baby Fence Rail Quilt is finished. It's new owner came to collect it yesterday afternoon an hour or two after I had put the last stitches into the binding. It was the first time Bill and I had met baby Georgia, who is just four weeks old, and we were captivated

|

| Please excuse my ankles |

I wasn't feeling game enough to do the quilting on the Singer 201K and defaulted to my 'go to' quilter the Singer 401K fitted with the walking foot. I used the same putty-coloured thread to secure the layers as I had used to piece the quilt top. It shows up better from the back.

The fence rail blocks finished at six inches and used the corners of these blocks are the reference point for the diagonal lines of quilting over the central part of the quilt. In this way the lines of quilting are four and a quarter inches apart which should be a nice density for a baby quilt. I quilted in the ditch around the inner border.

This picture shows how well Bill's choice for the backing fabric works. I think it pops without clashing. When I was binding the quilt I wanted to do this in exactly the same way I bound the Log Cabin quilt earlier in the year. I had the blog to remind me but I hadn't been very detailed. I couldn't for the life of me recall which machine I had used to sew the binding onto the front of the Log Cabin quilt. So here is a note to myself for future reference:

The fence rail blocks finished at six inches and used the corners of these blocks are the reference point for the diagonal lines of quilting over the central part of the quilt. In this way the lines of quilting are four and a quarter inches apart which should be a nice density for a baby quilt. I quilted in the ditch around the inner border.

This picture shows how well Bill's choice for the backing fabric works. I think it pops without clashing. When I was binding the quilt I wanted to do this in exactly the same way I bound the Log Cabin quilt earlier in the year. I had the blog to remind me but I hadn't been very detailed. I couldn't for the life of me recall which machine I had used to sew the binding onto the front of the Log Cabin quilt. So here is a note to myself for future reference:

- For the fence rail quilt I used the 401G with the walking foot to sew the binding onto the front of the quilt

- I left eight inch tails at the beginning and of the binding which really made it a lot easier to join them together later

- I then used a size three between and a ladder stitch to sew the binding onto the back of the quilt using the line of machine stitching from the front as a guide for my hand sewing - yet again this took me hours but I still feel it's time well spent. After all this is a gift for a very special little bundle.

|

| A well-padded friend maybe just as cuddly as a quilt |

Sunday, 22 September 2013

Has anyone ever heard of a Hussif?

I hadn't until I was chatting to follower Ken a week or two ago. I thought I knew what he was talking about until Monday when I treated myself to a copy of the Merchant & Mills SEWING BOOK. When I saw a photograph of their project Hussif I realised the picture I had in my head was well off beam. It turns out that a Hussif is a pocket sewing kit with some whimsical etymology thrown in for good measure.

I am rather taken by the Merchant & Mills SEWING BOOK. It's an aesthetically pleasing object in its own right and the projects inside are, for the main part, non-gender-specific which makes a welcome change for the male seamster.

As a confirmed old bachelor with some heavy unbleached calico on his hands I figured that a Hussif is the nearest I am likely to get to a housewife and resolved to knock one up [perhaps I should rephrase that!?]

Here are some pictures of my version

There are seven pockets forbits and bobs sewing notions. I made mine the same size as the instructions but the book encourages makers to adjust pocket sizes to fit the objects in their own sewing kit. The striped ticking covers two layers of cotton quilt wadding which form a pin cushion cum needle case.

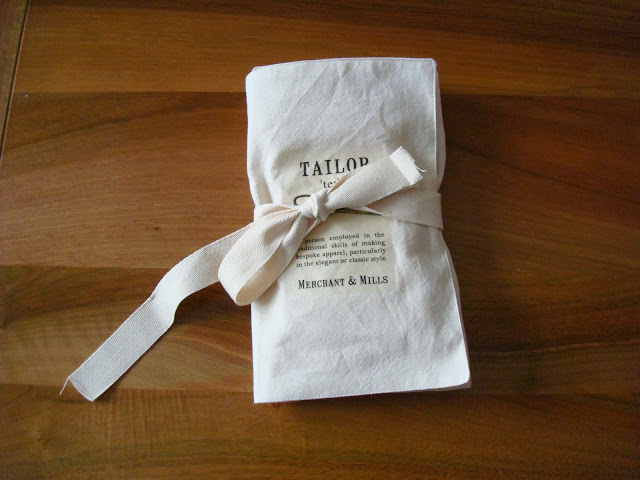

Here is the Hussif all furled up and tied shut. To give you an idea of size the cotton webbing tape is 25mm (yes I've gone metric today) or one inch wide. I may trim the tape down a bit once things have stretched out a bit.

The first of two big adventures in making this project was printing the downloadable Merchant and Mills graphic onto what can only be described as magic paper and then transferring this to the front of the Hussif using the iron.

I think I may have overcooked the transfer slightly and the instructions on where to position it were not Gavin-proof (I may have got the graphic upside down) but overall I am pleased with the effect. I am left with some mixed feelings about putting a company logo onto an item I have made but I like the look of the finished project and I have tried out something I never would have done otherwise. My mind is now teaming with ideas for some kind of Oil & Thread transfer. Possibly featuring a hen if I can find copyright free image to use.

Adventure number two is a Singer 401G related discovery and one for the seam guide junkies amongst us (you know who you are). I have discovered that the toe of the general purposes foot can be made to sit under the seam guide. This is shown in the section of the Manual which shows how to blind stitch hems using the "BO" setting. I realised that, with the needle centred (red lever at position 3), this gives scant ⅛ seam allowance.

I am rather taken by the Merchant & Mills SEWING BOOK. It's an aesthetically pleasing object in its own right and the projects inside are, for the main part, non-gender-specific which makes a welcome change for the male seamster.

As a confirmed old bachelor with some heavy unbleached calico on his hands I figured that a Hussif is the nearest I am likely to get to a housewife and resolved to knock one up [perhaps I should rephrase that!?]

Here are some pictures of my version

There are seven pockets for

Here is the Hussif all furled up and tied shut. To give you an idea of size the cotton webbing tape is 25mm (yes I've gone metric today) or one inch wide. I may trim the tape down a bit once things have stretched out a bit.

The first of two big adventures in making this project was printing the downloadable Merchant and Mills graphic onto what can only be described as magic paper and then transferring this to the front of the Hussif using the iron.

I think I may have overcooked the transfer slightly and the instructions on where to position it were not Gavin-proof (I may have got the graphic upside down) but overall I am pleased with the effect. I am left with some mixed feelings about putting a company logo onto an item I have made but I like the look of the finished project and I have tried out something I never would have done otherwise. My mind is now teaming with ideas for some kind of Oil & Thread transfer. Possibly featuring a hen if I can find copyright free image to use.

Adventure number two is a Singer 401G related discovery and one for the seam guide junkies amongst us (you know who you are). I have discovered that the toe of the general purposes foot can be made to sit under the seam guide. This is shown in the section of the Manual which shows how to blind stitch hems using the "BO" setting. I realised that, with the needle centred (red lever at position 3), this gives scant ⅛ seam allowance.

When would want a scant ⅛ seam allowance? Well I found it handy when edge stitching the Hussif. I hope you agree that the results are pretty tasty.

I am planning to hold on to this particular Hussif myself. I have something in mind for it. I really enjoyed putting this together. It's a good way to spend a Saturday afternoon. At this point in September I am thinking that one or two of these, filled with some 'heritage' style notions might make good Christmas presents.

Wednesday, 4 September 2013

Baby Fence Rail Pt VI

A couple of weekends ago I finally got to the shops to buy some wadding (batting) so that I can finish the Baby Fence Rail quilt. That was the easy part. I still needed to choose a backing fabric (remember the green stuff I bought for the purpose and then turned into a shirt?). After trolling the streets of London for an hour or two I settled on some cassis-coloured (that's pale purple to you and I) cotton sateen lining fabric. Surprisingly the colour combination works.

Having bought the missing ingredients I discovered new enthusiasm for this quilt. So I wasted no time and gave the wadding a bath! This is supposed to remove excess cotton oil which could mark the quilt and to preshrink the wadding. Some people do and some people don't. I guess I am just one of those guys who do.

With the wadding and backing fabric washed, preshrunk and dried I layered the quilt sandwich in the usual way. Pausing only to spend a few minutes deliberating over the right/wrong side of the cotton sateen. I decided to put the shiny side out. I thought that this would feel nicest if anyone should try sleeping under the quilt.

When I sandwiched the Log Cabin quilt one of my readers was rather alarmed by how few pins I used in my basting and I solemnly swore to use more on my next project. I even bought some fancy curved safety pins. I basted at approximately four inches or less and here is a photograph to prove it. I must confess that the whole thing feels a lot firmer and I am hoping it will make the quilting process easier.

Now for the really big news. In an exclusive announcement made this evening our spokesman can confirm that this quilt will be quilted OUT of THE DITCH!!

I have started to mark the quilt top with inch wide masking tape. I am going to quilt the centre of the quilt with a diagonal cross hatched grid. Tomorrow, with a fair wind, I may get the Singer 401G out and lay down that first row of quilting...

Subscribe to:

Comments (Atom)